China Conele Planetary Mixer Manufacturers – Intensive Mixer – CO-NELE Machinery Detail:

Mixing principle

CO-NELE CR intensive mixer applies counter-current mixing principle which provides optimal homogeneous mixture in shortest time.

The eccentrically assembled multi-level high speed mixing tools rotating in clockwise direction provides high intensity mixing.

The inclined arranged rotating mixing pan in anti-clockwise tumbles the material,provides mixing effect in vertical and horizontal and bring the materials to high speed mixing tools.

The multi-purpose functional tool deflects the materials,prevent materials from sticking to the mixing pan bottom and wall and help to discharge.

The rotating speed of mixing tools and mixing pan could both run at various speeds for specific mixing process,in the same process or different batches

Function of mixer

The multi-functional mixing system can be used for many different applications, e.g. for mixing, granulating, coating, kneading, dispersing, dissolving, defibering and many more.

Advantages of the mixing system

the advantages for the mixed product:

Higher tool speeds can be used for example to

-optimally solubilize fibers

-completely pulverize pigments

-optimize mixing of fine fractions

-manufacture suspensions with a high solid content

Medium tool speeds are used to

-achieve mixtures with a high mixture quality

At lower tool speeds

-lightweight additives or foams can be gently added to the mixture

Mixer batchwise

In contrast to other mixing systems,the throughput rate and mixing intensity of CO-NELE CR intensive batch mixers can be adjusted independently

of each other.

The mixing tool can run at variable speeds from fast to slow

This allows the power input into the mixture to be adapted to the specific mix

Hybrid mixing processes are made possible e.g.slow–fast–slow

Higher tool speeds can be used for example to:

-optimally solubilize fibers

-completely pulverize pigments,optimize mixing of fine fractions

-manufacture suspensions with a high solid content

Medium tool speeds are used to achieve mixtures with a high mixture quality

At low tool speeds,lightweight additives or foams can be gently added to the mixture

The mixer mixes without separating the mixture;100%material agitation during each revolution of the mixing pan.Eirich intensive batch mixers are available in two series with a usable volume ranging from 1 to 12,000 liters.

Features

High performance mixing effect,consistent high quality homogeneous mixture batch after batch

Compact design,easy to install,suitable for new plant and improving the existing production line.

Robust construction,low wear,built to last,long service life.

Intensive Mixer application industry

ceramics

Molding materials,molecular sieves,proppants,varistor materials,dental materials,ceramic tools,abrasive materials,oxide ceramics,grinding balls,ferrites,etc.

building materials

Porous media of bricks,expanded clay,perlite,etc.,refractory ceramsite,clay ceramsite,shale ceramsite,ceramsite filter material,ceramsite brick,ceramsite concrete,etc.

Glass

Glass powder,carbon,leaded glass frit,waste glass slag,etc.

metallurgy

Zinc and lead ore,alumina,carborundum,iron ore,etc.

chemical

Slaked lime,dolomite,phosphate fertilizers,peat fertilizers,mineral materials,sugar beet seeds,fertilizers,phosphate fertilizers,carbon black,etc.

Environmental friendly

Cement filter dust,fly ash,sludge,dust,lead oxide,fly ash,slag,dust,etc.

Carbon black,metal powder,zirconia

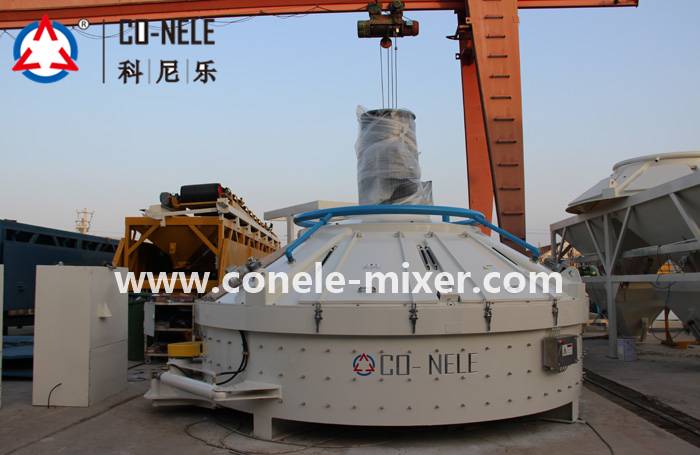

Product detail pictures:

Related Product Guide:

Choosing the Best Concrete Mixer for the Job

The Advancement of Concrete Mixer Through the Years

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for China Conele Planetary Mixer Manufacturers – Intensive Mixer – CO-NELE Machinery, The product will supply to all over the world, such as: Ghana, Angola, Benin, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!