We stick to our company spirit of “Quality, Effectiveness, Innovation and Integrity”. We purpose to create far more value for our shoppers with our abundant resources, sophisticated machinery, experienced workers and exceptional expert services for China Gold Supplier for -speed Cream Disperser Mixer Intensive Chemical Lab Emulsifier Homogenizer, Now we have four leading products and solutions. Our items are very best sold not only during the Chinese current market, but also welcomed inside the international sector.

We stick to our company spirit of “Quality, Effectiveness, Innovation and Integrity”. We purpose to create far more value for our shoppers with our abundant resources, sophisticated machinery, experienced workers and exceptional expert services for Lab -speed Disperser, Lab Homogenizer Emulsifier, Lab Homogenizer For Cream, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

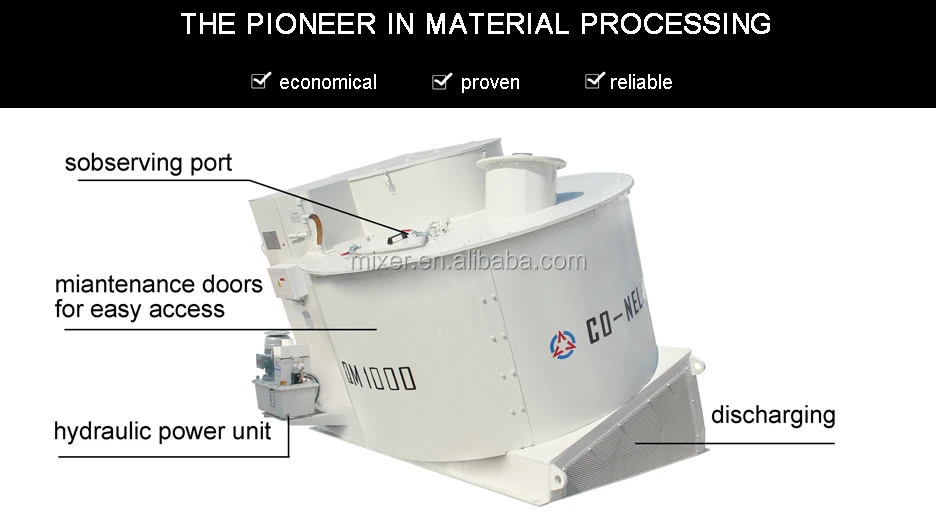

Function of intensive mixer

mixing,granulation,reaction,emulsification,dispersion,plasticizing,forming,exhaust,crushing,fibrosis,decompositon,coalescence

| SPECIFICATIONS FOR CQM SERIES INETNSIVE MIXERS | |||||||||||

| Model | CQM10 | CQM40 | CQM50 | CQM100 | CQM150 | CQM250 | CQM330 | CQM500 | CQM750 | CQM1000 | |

| Mixing Silo | Mixing Volume | 15 | 60 | 75 | 150 | 225 | 375 | 500 | 750 | 1125 | 1500 |

| Silo Dimensions | Φ350×275 | Φ500×360 | Φ800×500 | Φ850×600 | Φ900×700 | Φ1100×750 | Φ1250×800 | Φ1500×820 | Φ1800×850 | Φ1900×890 | |

| Inclined Angle | 30° | 30° | 30° | 30° | 20° | 20° | 20° | 20° | 20° | 20° | |

| Rotating Speed | 36rpm | 27rpm | 32rpm | 22rpm | 20rpm | 19rpm | 17rpm | 16rpm | 15rpm | 11rpm | |

| Dirving Motor Power | 1.1KW | 1.5KW | 4.5KW | 5.5KW | 7.5KW | 11KW | 18.5KW | 18.5KW | 15KW | 30KW | |

| Mixing Rotor | Rotor Diameter | 180mm | 280mm | 350mm | 450mm | 580mm | 650mm | 700mm | 800mm | 900mm | 1000mm |

| Rorating Speed | 400rpm | 1200rpm | 700rpm | 750rpm | 600rpm | 300rpm | 500rpm | 500rpm | 500rpm | 500rpm | |

| Driving Motor Power | 4kw | 15kw | 15kw | 22kw | 22kw | 37kw | 75kw | 75kw | 75kw | 75kw | |

| Discharging Door | Discharging Way | Silo Inclines to Discharge | Hydraulic Central Discharge | ||||||||

| Pressure | 70Kg/cm² | ||||||||||

| Driving Motor Power | 0.75kw | 0.75kw | 2.2kw | ||||||||

Main Features

- Intensive mixer can be design according to countercurrent principle or cross flow principle.

- The mixer can drive the trough move together .At the same time,the mixing device can cut material . In the complex mixing,can get very good mixing effect.

- In the turning mixing trough, material be pushed the scraper . The turn over. That promote the mixing up and down.

- Mixing blade can strip the material at the bottom and side of mixer. Can shorten the discharging time.

- According to the mixture material,CO-NELE lets you choose from among a number of proven materials for inhibiting wear, hardox liner, welding liner, ceramic liner

Exhibition