China Js Twin Shaft Concrete Mixer – 90m3/h sationary concrete batching plant – CO-NELE Machinery Detail:

HZN90 concrete batching plant is mainly composed 0f PLD2400 batching machine, JS1500 TWIN SHAFT concrete mixer or CMP1500 planetary concrete mixer ,cement silos, automatic computer control system, electronic weighing, screw conveyor and others.It can mix fluidity concrete, plastic concrete, hard concrete and other proportioning concrete.

CO-NELE stationary concrete batching plants are being manufactured since 1993’s. HZN120stationary concrete batching plant from the series is equipped with2250/1500 l. twin shaft concrete mixer or planetary concrete mixer.

HZN90 Stationary Concrete Batching Plant which has 90 m³/h concrete production capacity is the product of CO-NELE’s high quality and advanced technology and provides the following advantages to its users:

- Flexibility in the configuration

- High production performance and high productivity

- Easy installation due to its modular structure

- Variable layout options

- Wide operating and maintenance areas

- Easy maintenance and low operating costs

plants are mostly preferred for projects which require relatively high concrete production capacity and will take place for a long period of time in the same location.

Why stationary concrete batching plant?

High production capacity

Easy operation and maintenance in wide areas

High efficiency

Flexibility in configuration

Conformity with special site layouts

| stationary concrete batching plants | ||||||

| Model | HZN25 | HZN35 | HZN60 | HZN90 | HZN120 | HZN180 |

| Productivity (m³/h) | 25 | 35 | 60 | 90 | 120 | 180 |

| Discharge Height (mm) | 3800 | 3800 | 4000 | 4200 | 4200 | 4200 |

| Mixer Model | JS500/CMP500 | JS750/CMP750 | JS1000/CMP1000 | JS1500/CMP1500 | JS2000/CMP2000 | JS3000/CMP3000 |

| Working Cycle Time (s) | 72 | 72 | 60 | 60 | 60 | 60 |

| Batching Machine Model | PLD800 | PLD1200 | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Affregate Number | 3 | 3 | 4 | 4 | 4 | 4 |

| Max.Aggregate Size (pebble/gravel) | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm |

| Aggregate Weighing Accuracy | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement Weighing Accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Water Supply Weighing Accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Admixtures Weighing Accuracy | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Note: Any change of technical data shall not be advised additionally. | ||||||

Application

The Fixed Concrete Batching Plant can be used for industry, construction, road, railway, bridge, water conservation, ports, and so on.

Prefabricated parts:

Cement pipe,

Block brick

Subway tube

Pipe pile

Pavement brick

Wall panel

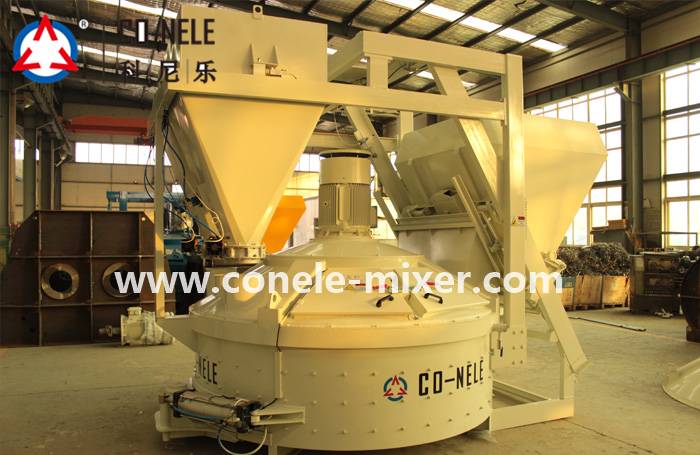

Product detail pictures:

Related Product Guide:

All About Concrete Mixer

Concrete Mixers – Types of Concrete Mixers

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for China Js Twin Shaft Concrete Mixer – 90m3/h sationary concrete batching plant – CO-NELE Machinery, The product will supply to all over the world, such as: Senegal , Birmingham , Puerto Rico , We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.