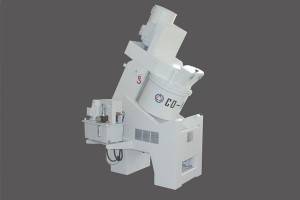

CR02 laboratory intensive mixer is a flexible, high-performance mixing equipment suitable for R&D and small-scale production. Here is a brief introduction:

CR02 laboratory intensive mixer Features

Good mixing effect: The unique mixing principle ensures that 100% of the materials are mixed, and the best product quality can be obtained in the shortest time, whether it is high-speed mixing to achieve the best dispersion of fibers, the best mixing of powdery fine materials and the production of suspended solids with high solid content, or medium-speed mixing to obtain high-quality mixtures, or low-speed mixing to gently add lightweight additives or foams, it can be done well.

High balling rate: Through the principle of strong countercurrent, the equipment has the advantages of high balling rate and uniform particle size, and the granulation time and granulation uniformity can be efficiently controlled.

Adjustable speed: The rotating mixing barrel and granulation tool group can be controlled by variable frequency, and the speed is adjustable. The particle size can be controlled by adjusting the speed.

Convenient unloading: The unloading method is tipping unloading or bottom unloading (hydraulic control), which is fast and clean, and easy to clean.

Multiple functions: It has multiple functions such as mixing, granulation, coating, kneading, dispersion, dissolution, and defibration.

Safety and environmental protection: The whole process of mixing and granulation is fully enclosed, without dust pollution, safe and environmentally friendly. Heating and vacuum functions can be added according to user needs. Equipped with an independent control cabinet, it can be connected to the plc control system to achieve full automatic control.

Application areas

Ceramics: used for the production of molecular sieves, proppants, grinding materials, grinding balls, ferrites, oxide ceramics, etc.

Building materials: such as porosity agents are used in the preparation of bricks, expanded clay, perlite, etc., and can also be used to produce refractory ceramsite, clay ceramsite, shale ceramsite, ceramsite filter material, ceramsite bricks, ceramsite concrete, etc.

Glass: It can handle glass powder, carbon, lead glass mixture, etc.

Metallurgy: Suitable for mixed processing of zinc and lead ore, alumina, silicon carbide, iron ore, etc.

Agricultural chemistry: It can be used for the processing of lime hydrate, dolomite, phosphate fertilizer, peat fertilizer, mineral compounds, beet seeds, etc.

Environmental protection: It can handle cement filter dust, fly ash, mud, dust, lead oxide, etc.

Technical parameters: The capacity of the CR02 laboratory high-power mixer is generally 5 liters.