High Intensity Mixer Blades Manufacturers – Refractory mixer – CO-NELE Machinery Detail:

The refractory mixer is a mixing device developed by co-nele according to the characteristics of the refractory material. After the refractory material is rigorously compounded, it is efficiently mixed to form a high-quality material with uniform composition and good granules.

Tilting intensive mixer features

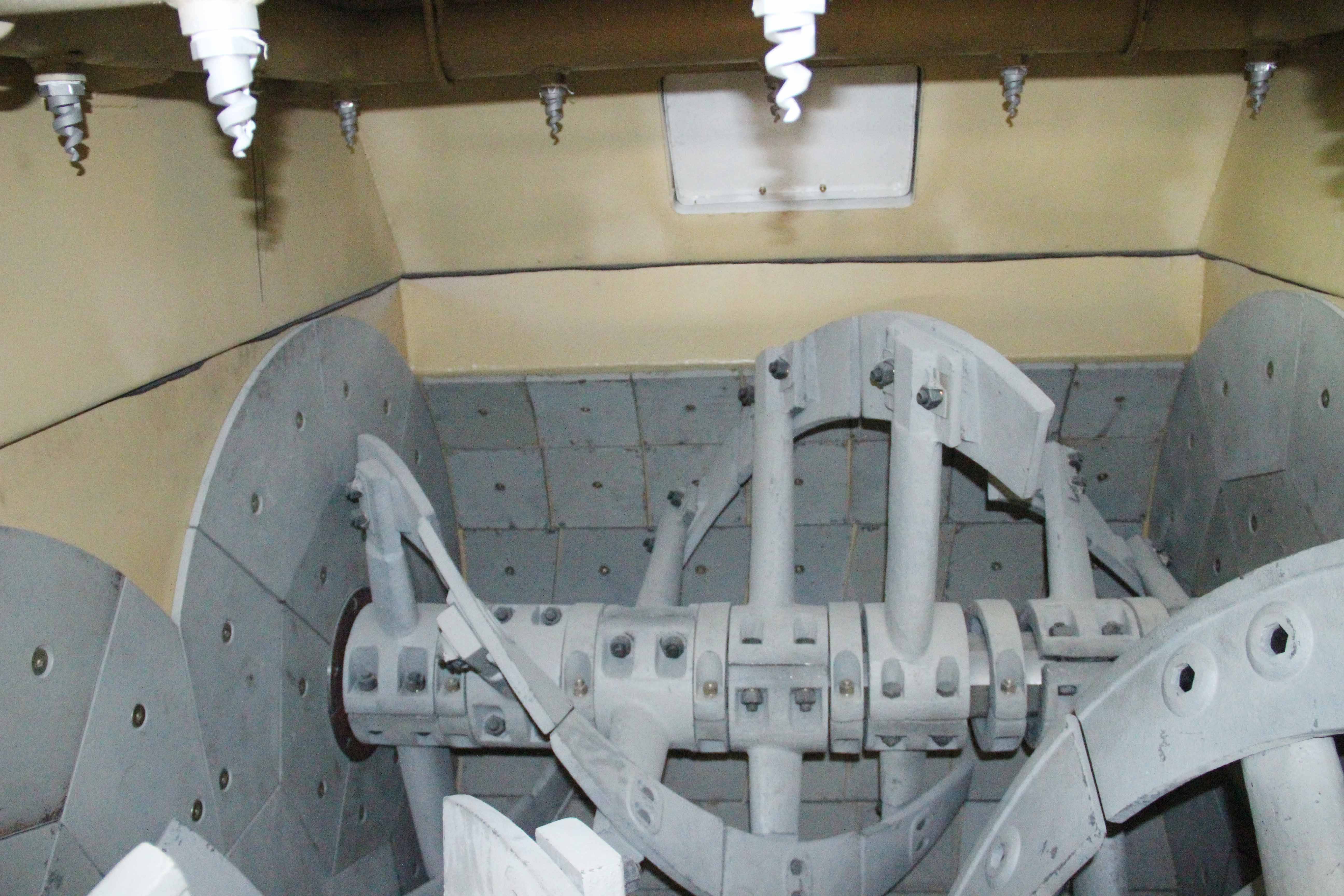

The inclined intensive mixer uses the gravity of the barrel and the forced agitation of the agitating rotor. The mixing effect is representative of all refractory mixers. The refractory mixer combines the double barrel of the inclined barrel design with the mixer to form a three-dimensional mixing of the mixer, mixing no dead angle, high uniformity, fast mixing speed, fast and clean discharge. The refractory mixer has a strong mixing process but does not cause damage or wear to the material.

What are the functions of the refractory mixer?

Significantly improve the molding properties of refractories;

The mud which is stirred and mixed is uniform and homogenous, and does not segregate;

Under the premise of ensuring plasticity, the density of the mixture is high, and there is no looseness of the mud.

Structural properties of refractory mixers

1. The refractory mixer adopts the scientifically designed mixing technology, and the mixing can achieve the best dispersion and uniformity;

2. The structure of refractory mixer equipment is not complicated, the overall design is compact, and the operation is safe and reliable.

3. The reasonable agitating structure design of the mixer makes the mixing more complete, and the unloading scraper is installed to make the discharging quick and clean and easy to clean;

4, superior control system, can carry out precise operation, high work efficiency, low power consumption

5. Special mixing tool design to meet the uniform mixing of various materials. The whole equipment has been treated with wear resistance and corrosion resistance. The related parts are strong and durable, and the overall failure rate of the equipment is low and easy to maintain;

6. The refractory mixer equipment has good sealing performance and effectively prevents the mixture from being polluted by the environment.

Product detail pictures:

Related Product Guide:

Concrete Mixers – Types of Concrete Mixers

Choosing the Best Concrete Mixer for the Job

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for High Intensity Mixer Blades Manufacturers – Refractory mixer – CO-NELE Machinery, The product will supply to all over the world, such as: Detroit, Canada, Leicester, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to provide customers with high quality products, provide high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.