In order to ensure the concrete twin-shaft mixer can be used better, prolong the service life as much as possible, and create more economic benefits for you, please pay attention to the following matters when using. Please check whether the oil level of the reducer and hydraulic pump is reasonable before the first use. The oil level of the reducer should be in the middle of the oil mirror. The hydraulic oil pump should be refueled to the oil gauge 2 (the oil may be lost due to transportation or other reasons). Check it once a week later. Stirring step is first started after stirring, it is forbidden to start after feeding, or repeated feeding, otherwise it will lead to boring machine, affecting the performance and service life of the mixer. After the completion of each working cycle of the mixer, the inside of the cylinder must be thoroughly cleaned, which will effectively improve the life of the mixer and reduce power consumption.

Shaft end maintenance

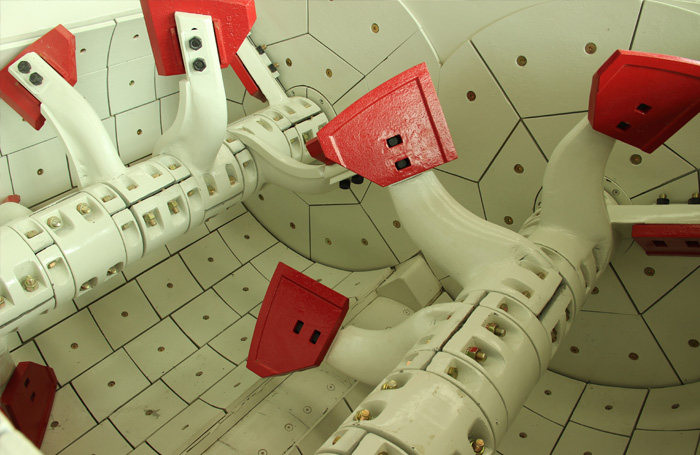

The shaft end seal is the most important position for the maintenance of the mixer. The shaft head housing (oil pump oiling position) is the main component of the shaft end seal. It is necessary to check the lubricating oil pump for normal oiling every day.

1、Pressure gauge with or without pressure display

2.、Is there any oil in the oil pump oil cup?

3、Whether the pump’s cartridge is normal or not

If an abnormality is found, it is necessary to stop the inspection immediately and continue working after troubleshooting. Otherwise, it will cause the shaft end to leak and affect the production. If the construction period is tight and cannot be repaired in time, manual oiling can be used.

Every 30 minutes. It is necessary to keep the lubricating oil inside the shaft end sufficient. The position of the end cover 2 is the research sealing ring and the skeleton oil seal, and the position of the outer casing 2 is the main shaft bearing, all of which need grease lubrication but do not consume only need to supply oil once a month, and the oil supply amount is 3 ml.

Consumable parts maintenance

When the concrete twin-shaft mixer is used for the first time or when the concrete is mixed to reach 1000 square meters, check whether all the mixing arms and scrapers are loose, and check them once a month. When the mixing arm, scraper, lining, and screw are found to be loose, tighten the bolt immediately to avoid the loosening of the stirrer arm, the scraper or the stirrer arm. If the tightening scraper bolt is loose, adjust the scraper and The gap between the bottom plates should not be greater than 6mm, and the bolts should be tightened).

Damage to the consumables

1、 Remove the damaged parts. When replacing the mixing arm, remember the position of the mixing arm to avoid damage to the mixing arm.

2、When replacing the scraper, remove the old part, put the stirring arm to the bottom and install a new scraper. Place a piece of steel (length 100mm wide, 50mm thick and 6mm thick) between the scraper and the bottom plate to fasten the scraper bolt. When the old parts are removed after replacing the lining, the new lining adjusts the upper and lower left and right gaps to evenly tighten the bolts.

Discharge door maintenance

In order to ensure the normal opening and closing of the discharge door, the position of the discharge door is easy to be squeezed during the blanking process, which will result in the unloading of the discharge door or the induction switch of the discharge door is not transmitted to the control system. The mixer cannot be produced. Therefore, it is necessary to clean up the deposits around the discharge door in time.

Post time: Aug-22-2018