Planetary mixers are ideal for producing paving bricks, due to their high mixing efficiency, uniform texture, and ability to handle hard concrete or clay mixtures. Here is a guide to choosing and using planetary mixers for paving bricks:

1. Why choose a planetary mixer for paving bricks?

High mixing efficiency: Planetary motion ensures that cement, sand, aggregates and pigments are thoroughly mixed.

Uniform texture: Key to producing high-quality, durable paving bricks.

Handles hard mixtures: Ideal for semi-dry concrete or clay mixtures used in brick production.

Short mixing cycle: Reduces production time.

Low maintenance cost: Robust construction for heavy-duty work.

2. Key features for choosing a planetary mixer

Capacity: Choose according to production volume (e.g. 300 liters, 500 liters, 750 liters or 1000 liters).

Mixing power: Single motor, guaranteed synchronization of transmission (e.g. 15KW-45kw), suitable for dense paving brick mixtures.

Mixing tools: Heavy-duty blades for abrasive materials.

Discharge system: Hydraulic or pneumatic bottom discharge for easy unloading.

Durability: Steel construction with wear-resistant lining.

Automation options: Timer-controlled mixing to ensure consistency.

3. Recommended mixing process for paving bricks

Raw materials:

Cement

Sand

Crushed stone/aggregate

Water (for semi-dry concrete)

Pigments (if colored bricks are required)

Optional: Fiber reinforcement for strength

Mixing steps:

Dry mixing: First mix cement, sand and aggregate.

Wet mixing: Gradually add water until a uniform semi-dry consistency is achieved.

Discharge: Pour the mixture into brick molds or automatic brick making machines.

Curing: After forming, the bricks are cured under controlled humidity and temperature.

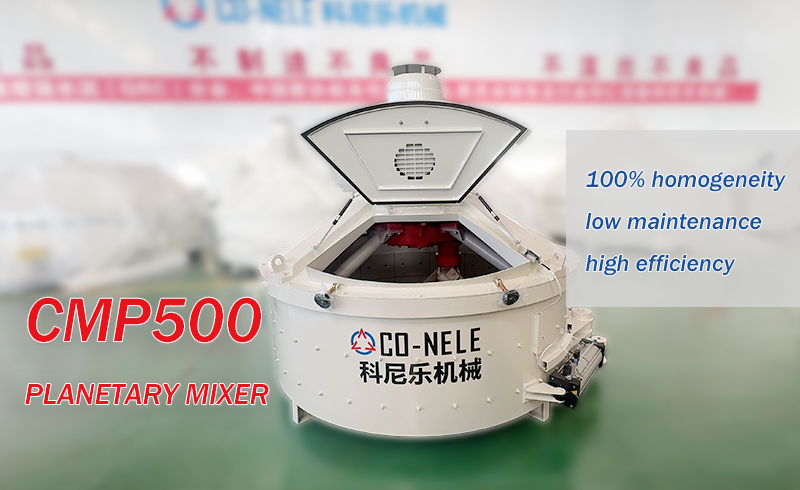

CO-NEE Top Planetary Mixer Brand for Paving Brick Production

4. Paving Brick Alternative Mixer

Pan Mixer: Similar to Planetary Mixer, but with different blade configuration.

Paddle Mixer: Suitable for Clay Bricks.

Forced Mixer: Ensures that the material does not stick.

Post time: Apr-15-2025