planetary mixer for refractory mixing

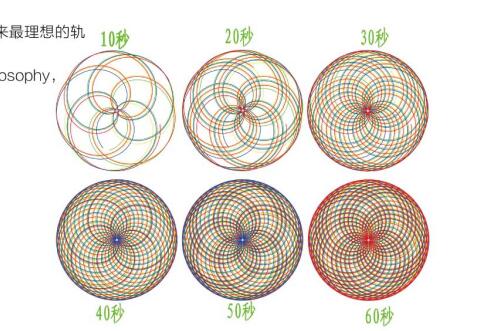

[Planetary refractory mixer trajectory]:

The revolution and rotation of the agitating blades enable the mixer to obtain large productivity without aggregating aggregates of various particle sizes and specific gravities. The material movement track in the mixing tank is smooth and continuous.

[Planet-type refractory mixer unloading device]:

According to the customer’s request, pneumatic and hydraulic means can be used to switch the discharge door, and the support structure and strength of the discharge door are effectively strengthened for industrial conditions. The unloading can be opened up to three and is equipped with special sealing devices to ensure a firm seal and reliable control.

[Planetary refractory mixer mixing device]:

Forced agitation by pressing and turning the material together when the planetary shaft with blades is installed in the mixing drum. The mixing blade is designed as a parallelogram (patented product), and the customer can re-use it according to the actual wear condition by 180°, effectively improving the utilization rate and life of the blade, and designing a special discharge scraper for the discharge speed to improve productivity.

[Planetary refractory mixer cleaning device]

The inlet pipe of the planetary refractory mixer cleaning device adopts an externally placed structure (patented product), and the water in the pipeline can be fully drained when the water is drained, so that the metering is more accurate, and the admixture can be effectively prevented. Mixing when cleaning the inside of a vertical axis planetary mixer causes residual problems that affect the quality of the mixture.

Post time: Jul-18-2018