OEM Factory for Construction Concrete Mixer - Twin shaft concrete mixer CHS – CO-NELE Machinery Detail:

Technical data

| 参数 型号 | CHS750 | CHS1000 | CHS1250 | CHS1500 | CHS2000 | CHS2500 | CHS3000 | CHS3500 | CHS4000 | CHS4500 | CHS5000 | CHS6000 |

| 进料容量(L) | 1125 | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 | 5250 | 6000 | 6750 | 7500 | 9000 |

| 进料重量(Kg) | 1800 | 2400 | 3000 | 3600 | 4800 | 6000 | 7200 | 7200 | 9600 | 10800 | 12000 | 14400 |

| 公称容量(L) | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 3000 | 4000 | 4500 | 5000 | 6000 |

| 搅拌臂个数 | 2×5 | 2×6 | 2×6 | 2×7 | 2×7 | 2×8 | 2×9 | 2×9 | 2×10 | 2×10 | 2×10 | 2×11 |

| 电机功率(Kw) | 30 | 37 | 45 | 55 | 37×2 | 45×2 | 55×2 | 65×2 | 75×2 | 75×2 | 90×2 | 110×2 |

| 泵站功率(Kw) | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 |

| 整机重量(Kg) | 4500 | 5000 | 5500 | 6000 | 8400 | 9000 | 9500 | 9500 | 13000 | 14500 | 16500 | 19000 |

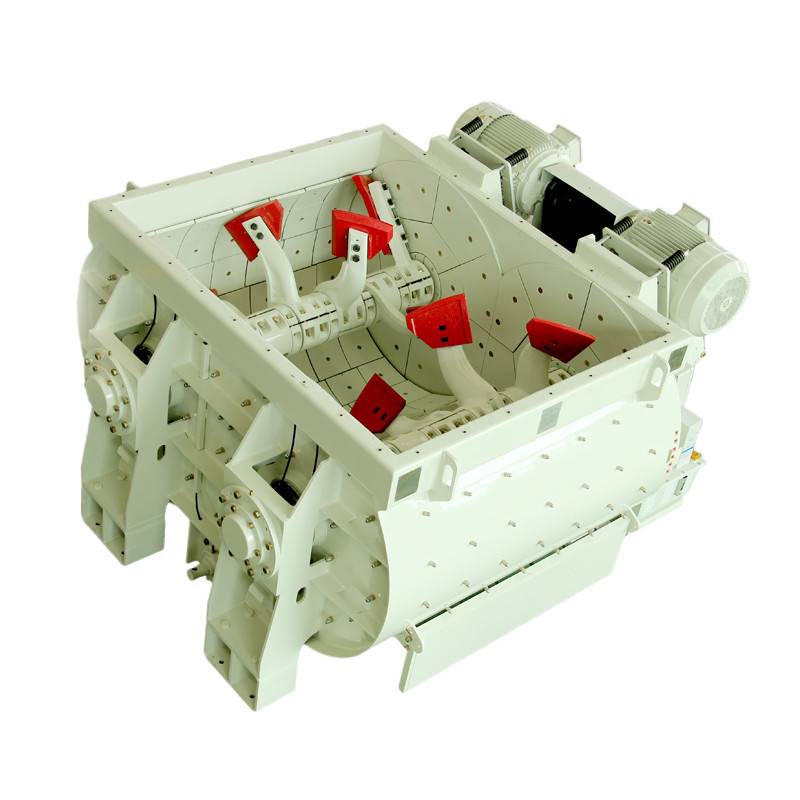

Product Introduction

CO-NELE mixer is designed compactly overall. All parts are installed in the mixing drum with small space occupation, making it easy to install and update the whole machine.

CO-NELE TWIN-SHAFT MIXER ADVANTAGES

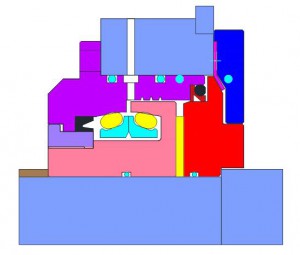

1)The shaft end seal is equipped with a floating oil seal ring, a special labyrinth seal structure composed of a seal and a mechanical seal, which has reliable sealing, high stability and long service life;

2) automatic lubrication system configuration, four independent oil pump, high working pressure, excellent performance;

3) On-mounted motor installation layout, patented belt self-tensioning device to improve transmission efficiency, to avoid excessive wear and damage to the belt, reduce maintenance costs,The large volume ratio design concept is adopted for the helium cylinder, which can effectively improve the mixing efficiency, prolong the service life of the shaft end seal, and reduce the probability of material shaft holding;

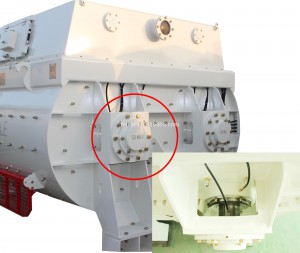

4) Discharging door adopts eccentric double sealing design to prevent material jamming and leakage, small wear, high sealing efficiency and long-lasting;

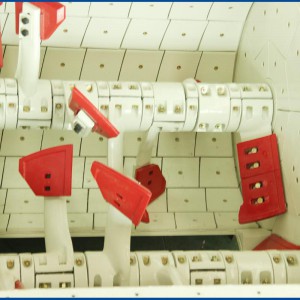

5) Stirring device adopts a patented design with an angle of 60°. Flow line casting of the stirring arm results in uniform mixing, low resistance, and low rate of material holding shaft;

6)Configured with military-grade planetary speed reducers with smooth transmission and high load capacity;

7) Optional original Italian reducer, original German automatic lubrication pump, high pressure cleaning device, temperature and humidity testing system;

Drive device

The drive device is driven with two planet-gear speed reducers. The design features compact design, stable transmission, low noise and long service life.

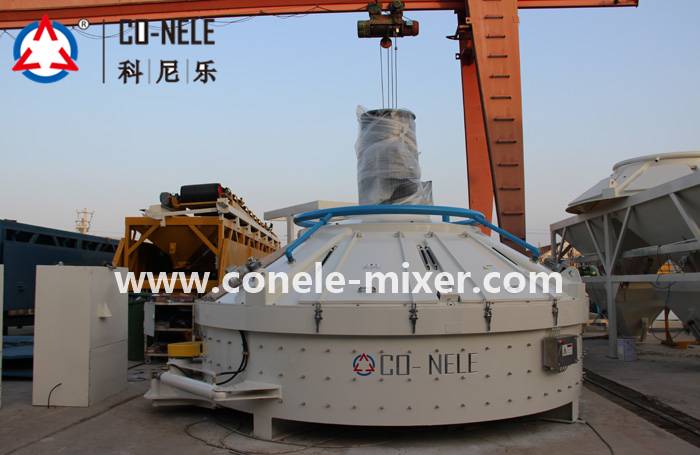

Shipping photos

Our factory

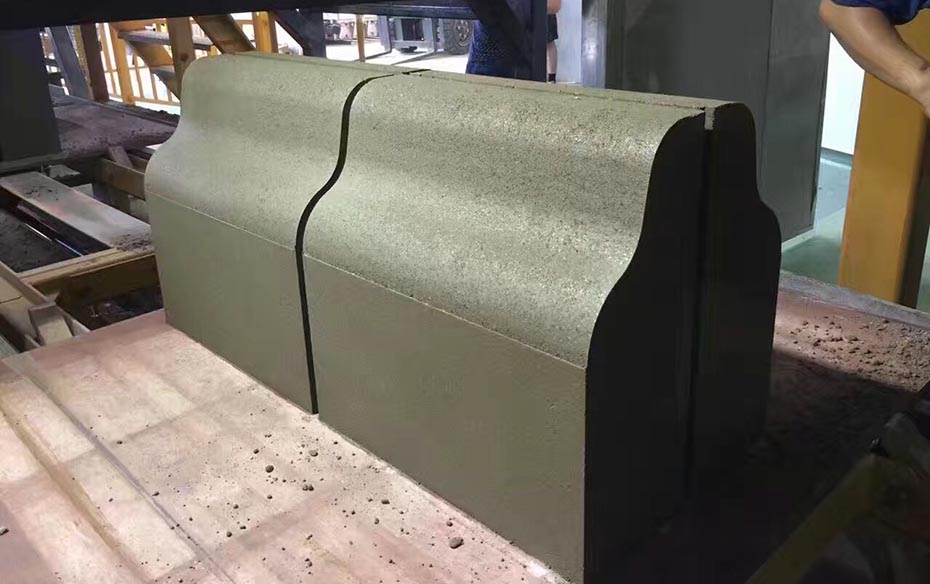

Equipment application

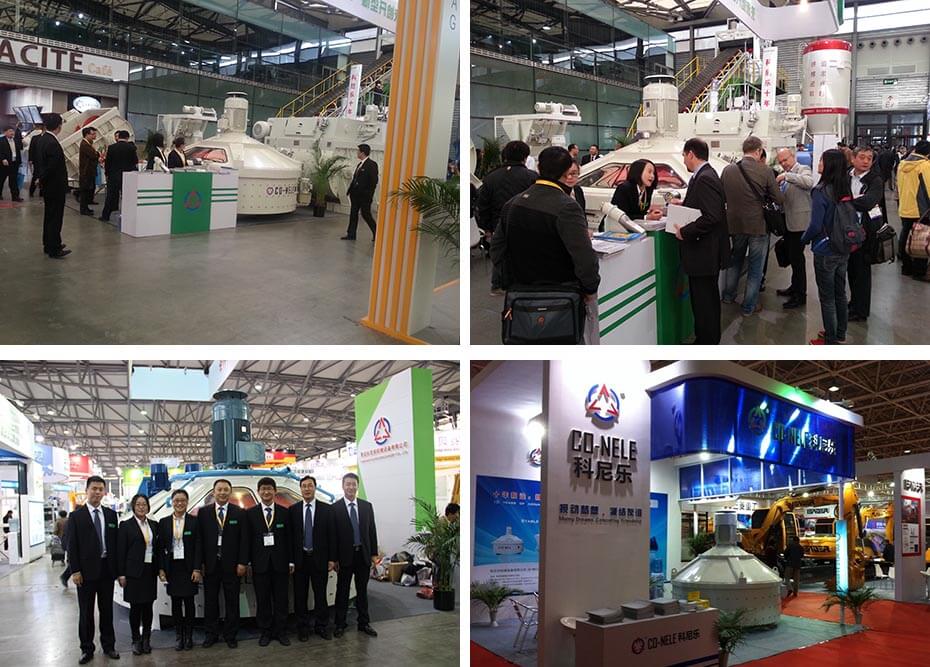

Exhibition

Product detail pictures:

Related Product Guide:

The Advancement of Concrete Mixer Through the Years

Concrete Mixers: Basic Information

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for OEM Factory for Construction Concrete Mixer - Twin shaft concrete mixer CHS – CO-NELE Machinery, The product will supply to all over the world, such as: azerbaijan, Brunei, Libya, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!