mixing,granulation,reaction,emulsification,dispersion,plasticizing,forming,exhaust,crushing,fibrosis,decompositon,coalescence

| SPECIFICATIONS FOR CQM SERIES INETNSIVE MIXERS |

| Model |

|

CQM10 |

CQM50 |

CQM100 |

CQM150 |

CQM250 |

CQM330 |

CQM500 |

CQM750 |

CQM1000 |

| Mixing Silo |

Mixing Volume |

15 |

75 |

150 |

225 |

375 |

500 |

750 |

1125 |

1500 |

| Silo Dimensions |

Φ350×275 |

Φ800×500 |

Φ850×600 |

Φ900×700 |

Φ1100×750 |

Φ1250×800 |

Φ1500×820 |

Φ1800×850 |

Φ1900×890 |

| Inclined Angle |

30° |

30° |

30° |

20° |

20° |

20° |

20° |

20° |

20° |

| Rotating Speed |

36rpm |

32rpm |

22rpm |

20rpm |

19rpm |

17rpm |

16rpm |

15rpm |

11rpm |

| Dirving Motor Power |

1.1KW |

4.5KW |

5.5KW |

7.5KW |

11KW |

18.5KW |

18.5KW |

15KW |

30KW |

| Mixing Rotor |

Rotor Diameter |

180mm |

350mm |

450mm |

580mm |

650mm |

700mm |

800mm |

900mm |

1000mm |

| Rorating Speed |

400rpm |

700rpm |

750rpm |

600rpm |

300rpm |

500rpm |

500rpm |

500rpm |

500rpm |

| Driving Motor Power |

4kw |

15kw |

22kw |

22kw |

37kw |

75kw |

75kw |

75kw |

75kw |

| Discharging Door |

Discharging Way |

Silo Inclines to Discharge |

Hydraulic Central Discharge |

| Pressure |

70Kg/cm² |

| Driving Motor Power |

0.75kw |

2.2kw |

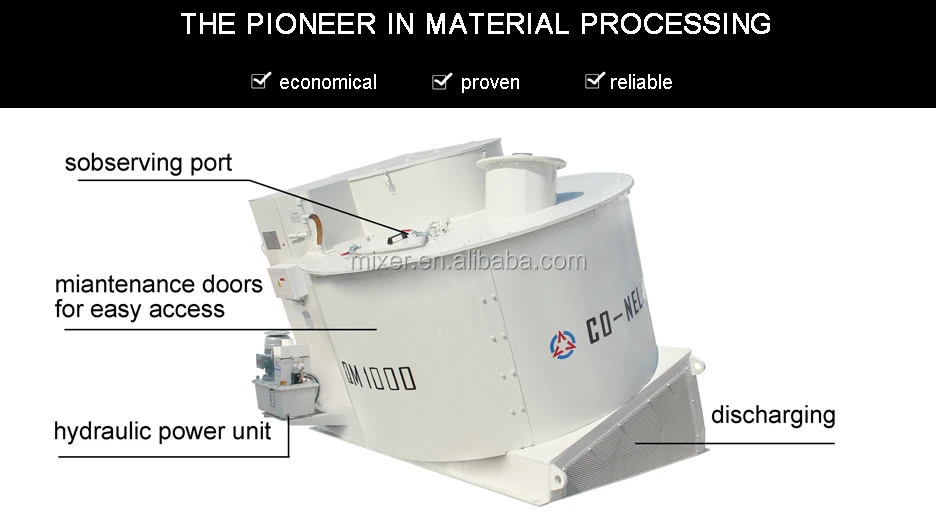

Main Features

- Intensive mixer can be design according to countercurrent principle or cross flow principle.

- The mixer can drive the trough move together .At the same time,the mixing device can cut material . In the complex mixing,can get very good mixing effect.

- In the turning mixing trough, material be pushed the scraper . The turn over. That promote the mixing up and down.

- Mixing blade can strip the material at the bottom and side of mixer. Can shorten the discharging time.

- According to the mixture material,CO-NELE lets you choose from among a number of proven materials for inhibiting wear, hardox liner, welding liner, ceramic liner