Our pursuit and corporation intention is to “Always satisfy our client requirements”. We continue to develop and style remarkable high-quality items for each our outdated and new shoppers and accomplish a win-win prospect for our customers likewise as us for Top Suppliers Lab Using Banbury Rubber Kneader/lab Use Rubber Kneader/lab Rubber Internal Mixer Qingdao, Welcome to post your sample and color ring to let’s produce according on your specification.Welcome your inquiry! Hunting forward to building long-term cooperation with you!

Our pursuit and corporation intention is to “Always satisfy our client requirements”. We continue to develop and style remarkable high-quality items for each our outdated and new shoppers and accomplish a win-win prospect for our customers likewise as us for Lab Rubber Kneader, Lab Using Banbury, Rubber Mixer, With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our merchandise, you should contact us now. We have been looking forward to hearing from you soon.

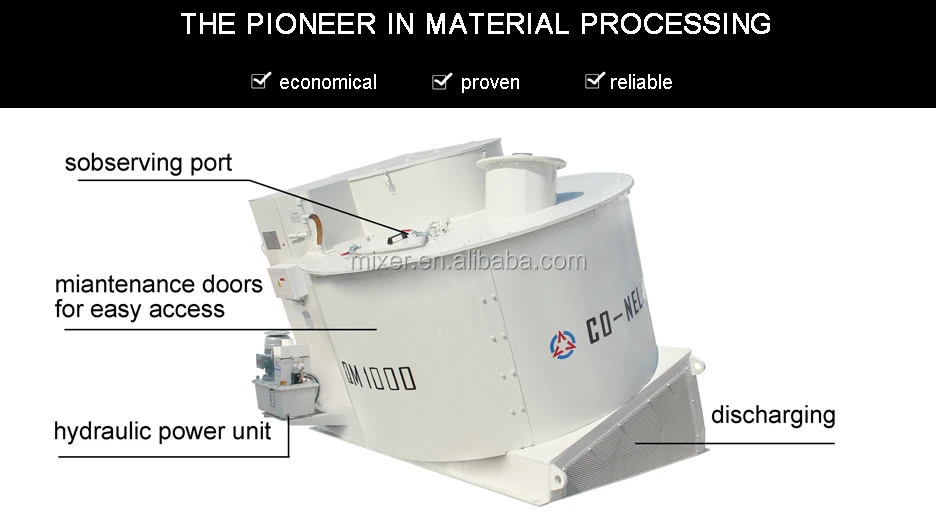

Function of intensive mixer

mixing,granulation,reaction,emulsification,dispersion,plasticizing,forming,exhaust,crushing,fibrosis,decompositon,coalescence

| SPECIFICATIONS FOR CQM SERIES INETNSIVE MIXERS | |||||||||||

| Model | CQM10 | CQM40 | CQM50 | CQM100 | CQM150 | CQM250 | CQM330 | CQM500 | CQM750 | CQM1000 | |

| Mixing Silo | Mixing Volume | 15 | 60 | 75 | 150 | 225 | 375 | 500 | 750 | 1125 | 1500 |

| Silo Dimensions | Φ350×275 | Φ500×360 | Φ800×500 | Φ850×600 | Φ900×700 | Φ1100×750 | Φ1250×800 | Φ1500×820 | Φ1800×850 | Φ1900×890 | |

| Inclined Angle | 30° | 30° | 30° | 30° | 20° | 20° | 20° | 20° | 20° | 20° | |

| Rotating Speed | 36rpm | 27rpm | 32rpm | 22rpm | 20rpm | 19rpm | 17rpm | 16rpm | 15rpm | 11rpm | |

| Dirving Motor Power | 1.1KW | 1.5KW | 4.5KW | 5.5KW | 7.5KW | 11KW | 18.5KW | 18.5KW | 15KW | 30KW | |

| Mixing Rotor | Rotor Diameter | 180mm | 280mm | 350mm | 450mm | 580mm | 650mm | 700mm | 800mm | 900mm | 1000mm |

| Rorating Speed | 400rpm | 1200rpm | 700rpm | 750rpm | 600rpm | 300rpm | 500rpm | 500rpm | 500rpm | 500rpm | |

| Driving Motor Power | 4kw | 15kw | 15kw | 22kw | 22kw | 37kw | 75kw | 75kw | 75kw | 75kw | |

| Discharging Door | Discharging Way | Silo Inclines to Discharge | Hydraulic Central Discharge | ||||||||

| Pressure | 70Kg/cm² | ||||||||||

| Driving Motor Power | 0.75kw | 0.75kw | 2.2kw | ||||||||

Main Features

- Intensive mixer can be design according to countercurrent principle or cross flow principle.

- The mixer can drive the trough move together .At the same time,the mixing device can cut material . In the complex mixing,can get very good mixing effect.

- In the turning mixing trough, material be pushed the scraper . The turn over. That promote the mixing up and down.

- Mixing blade can strip the material at the bottom and side of mixer. Can shorten the discharging time.

- According to the mixture material,CO-NELE lets you choose from among a number of proven materials for inhibiting wear, hardox liner, welding liner, ceramic liner

Exhibition