Twin Shaft Mixer Manufacturers – high intensive mixer product mixing Castable – CO-NELE Machinery Detail:

high intensive mixer product mixing Castable,

Function of intensive mixer

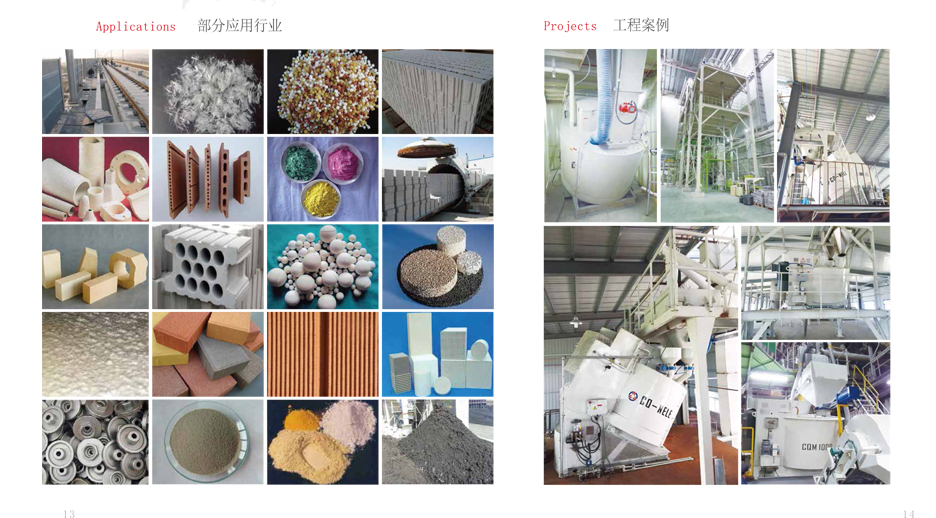

mixing,granulation,reaction,emulsification,dispersion,plasticizing,forming,exhaust,crushing,fibrosis,decompositon,coalescence

00:00

00:00

00:00

| SPECIFICATIONS FOR CQM SERIES INETNSIVE MIXERS | |||||||||||

| Model | CQM10 | CQM40 | CQM50 | CQM100 | CQM150 | CQM250 | CQM330 | CQM500 | CQM750 | CQM1000 | |

| Mixing Silo | Mixing Volume | 15 | 60 | 75 | 150 | 225 | 375 | 500 | 750 | 1125 | 1500 |

| Silo Dimensions | Φ350×275 | Φ500×360 | Φ800×500 | Φ850×600 | Φ900×700 | Φ1100×750 | Φ1250×800 | Φ1500×820 | Φ1800×850 | Φ1900×890 | |

| Inclined Angle | 30° | 30° | 30° | 30° | 20° | 20° | 20° | 20° | 20° | 20° | |

| Rotating Speed | 36rpm | 27rpm | 32rpm | 22rpm | 20rpm | 19rpm | 17rpm | 16rpm | 15rpm | 11rpm | |

| Dirving Motor Power | 1.1KW | 1.5KW | 4.5KW | 5.5KW | 7.5KW | 11KW | 18.5KW | 18.5KW | 15KW | 30KW | |

| Mixing Rotor | Rotor Diameter | 180mm | 280mm | 350mm | 450mm | 580mm | 650mm | 700mm | 800mm | 900mm | 1000mm |

| Rorating Speed | 400rpm | 1200rpm | 700rpm | 750rpm | 600rpm | 300rpm | 500rpm | 500rpm | 500rpm | 500rpm | |

| Driving Motor Power | 4kw | 15kw | 15kw | 22kw | 22kw | 37kw | 75kw | 75kw | 75kw | 75kw | |

| Discharging Door | Discharging Way | Silo Inclines to Discharge | Hydraulic Central Discharge | ||||||||

| Pressure | 70Kg/cm² | ||||||||||

| Driving Motor Power | 0.75kw | 0.75kw | 2.2kw | ||||||||

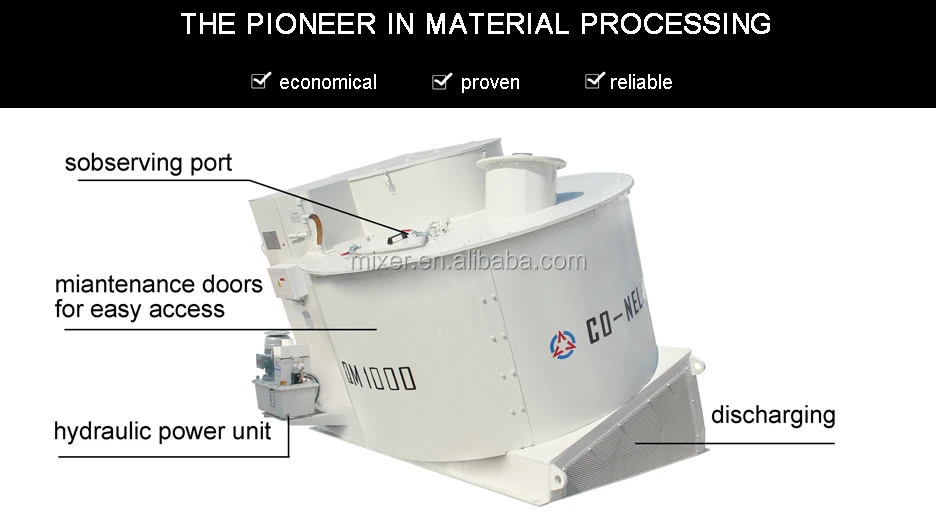

Main Features

- Intensive mixer can be design according to countercurrent principle or cross flow principle.

- The mixer can drive the trough move together .At the same time,the mixing device can cut material . In the complex mixing,can get very good mixing effect.

- In the turning mixing trough, material be pushed the scraper . The turn over. That promote the mixing up and down.

- Mixing blade can strip the material at the bottom and side of mixer. Can shorten the discharging time.

- According to the mixture material,CO-NELE lets you choose from among a number of proven materials for inhibiting wear, hardox liner, welding liner, ceramic liner

Product detail pictures:

Related Product Guide:

The Advancement of Concrete Mixer Through the Years

Choosing the Best Concrete Mixer for the Job

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Twin Shaft Mixer Manufacturers – high intensive mixer product mixing Castable – CO-NELE Machinery, The product will supply to all over the world, such as: Bulgaria , Colombia , Azerbaijan , To meet the requirements of specific customers for each bit more perfect service and stable quality merchandise. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!